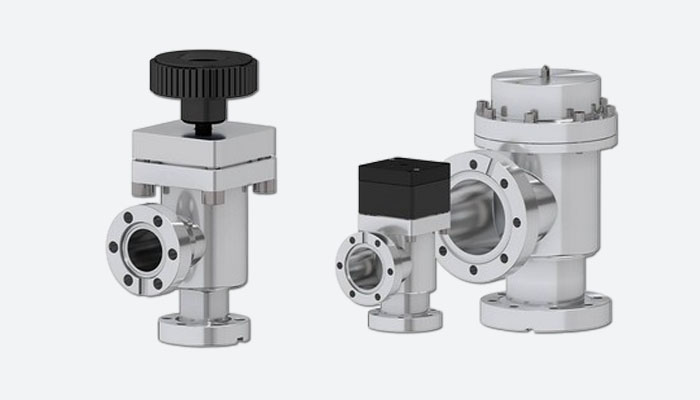

A vacuum valve is a mechanical device used to control the flow of gases or fluids in vacuum systems. These valves play a crucial role in maintaining the desired level of vacuum, controlling the pressure, and isolating different sections of the system when required.

Vacuum valves can be categorized into several types based on their operating mechanisms. One common type of vacuum valve is the gate valve, which uses a sliding gate mechanism to control the flow. When the gate is fully open, it allows for unrestricted flow, and when closed, it effectively seals off the system. Gate valves are often used in high-vacuum applications where a tight seal is necessary.

Another type is the butterfly valve, which consists of a flat disc that rotates within a pipe to control the flow. These valves are commonly used in processes that require quick actuation and efficient flow control.

Moreover, there are ball valves that use a spherical ball with a hole in it to regulate the flow of gas or fluid. By rotating the ball, the flow can be controlled or completely shut off. Ball valves are known for their durability and tight sealing capabilities.

Furthermore, vacuum valves may also be classified based on their vacuum range. Some valves are designed for high-vacuum applications, while others are suitable for rough vacuum or low-vacuum systems.

Choosing the right vacuum valve depends on factors such as the desired vacuum level, flow rate, compatibility with the gas or fluid being used, temperature and pressure requirements, and the specific application.

In addition to controlling the flow, some vacuum valves also feature additional functions such as pressure relief, venting, and isolation. These features enhance the safety and efficiency of the vacuum system.

Overall, vacuum valves are essential components in vacuum systems, allowing for precise control over the flow of gases or fluids and contributing to the overall performance and reliability of the system.